Application: T-shirt bag, packaging bag, construction film, agriculture film, lamination film etc

Suitable material: LDPE / LDPE+LLDPE

Film layer: 1 layer

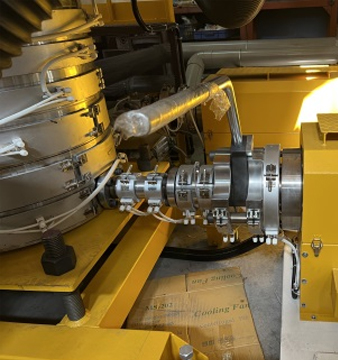

Screw L/D ratio: 30:1

Motor direct connection type gearbox

PID+SCR temperature controller

ABB or HITACHI inverter

Items/Models | L25/300 | L35/500 | L45/800 | L55/1100 | L65/1500 | L80/2000 | L100/2500 | L120/3000 | L150/3500 |

|---|---|---|---|---|---|---|---|---|---|

| Screw Diameter (mm) | 25 | 35 | 45 | 55 | 65 | 80 | 100 | 120 | 150 |

| Film Width (mm) | 50-200 | 150-400 | 400-700 | 600-1000 | 800-1350 | 1000-1800 | 1300-2300 | 1600-2800 | 2000-3000 |

| Output (kg/hr) | 6-15 | 15-33 | 25-50 | 40-90 | 60-130 | 120-200 | 180-280 | 240-360 | 350-500 |

| Film Thickness (mm) | 0.006-0.08 , depending on the material and film size | 0.025-0.25 | 0.025-0.25 | 0.03-0.25 | 0.04-0.25 | ||||

| Main Motor (HP) | 5 | 10 | 20 | 30 | 50 | 75 | 125 | 150 | 200 |

Automatically feeds raw materials into the extruder, ensuring a continuous supply and reducing manual labor.

Regulates the output of each layer in multi-layer film production, maintaining consistent thickness and quality.

Precisely measures and controls the amount of raw material being fed into the extruder, ensuring accurate composition and consistent product quality.

Adjusts the film thickness across the width automatically, improving uniformity and reducing material wastage.

Enhances the cooling and stabilization of the film bubble, leading to better film quality and production efficiency.

Provides additional cooling to the film bubble by using air, in order to have higher production speeds and improve film properties.

Rotates the die head to ensure even distribution of material and uniform film thickness.

Allows for the continuous filtering of impurities in the melt material, ensuring clean and high-quality film production without stopping the machine.

Automatically control and manage blower balance and increase cooling efficiency, enhancing improving production rates, width tolerance and bubble stability.

Treats the film surface to improve its adhesion properties, making it suitable for printing and laminating.

Adds texture or patterns to the film surface, gives the film a high surface friction coefficient, enhancing its anti-slip properties and the ability to better adhere to items.

Combine two winders, can make different use of film at the same time according to customer’s needs.

Used in winding systems to hold and center the film rolls, allowing for quick and secure roll changes.

Provides a user-friendly interface for operators to control and monitor the blown film machine, improving ease of use and operational efficiency.